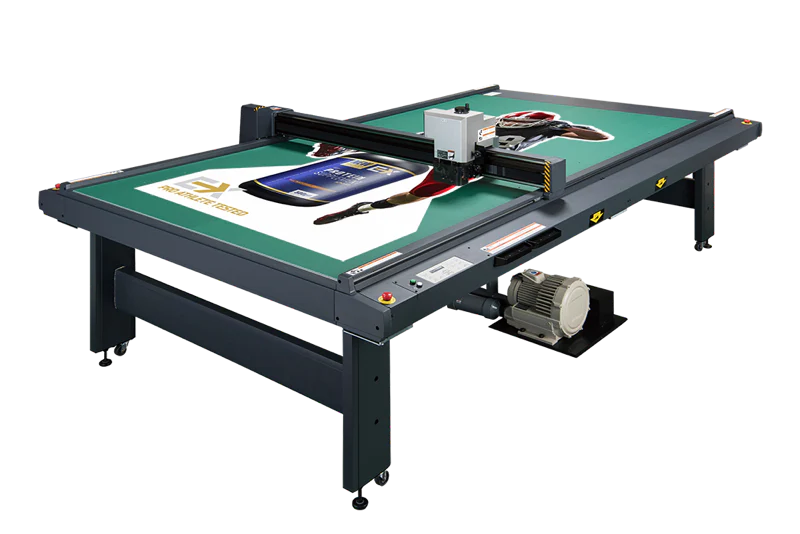

Mimaki Flatbed Cutting Plotter - CF22-1225 Series

Print & Cut, the optimal cooperated performance

More simple, more accurate.

[CF22-1225] is a flatbed cutting plotter based on cooperation with inkjet printers focusing to enhancement of usability.

[CF22-1225] is suitable to cut 4x8 material (1,220 x 2,440mm / 4x8ft) of popular size of signboard production for the combination use with [JFX200-2513], Mimaki UV flatbed inkjet printer.

Line-up

It is able to select the best cutter head type to fulfill your needs according to your cutting material and application.

- T / TF / RT head: For Industrial materials

- TD / RC head: For Package, Furniture

Model

| CF22-1225T-S | Effective cutting area: 1,220 x 2,500 mm (48.0 x 98.4") |

|---|---|

| CF22-1225TF-S | Effective cutting area: 1,220 x 2,500 mm (48.0 x 98.4") |

| CF22-1225RT-S | Effective cutting area: 1,220 x 2,500 mm (48.0 x 98.4") |

| CF22-1225TD-S | Effective cutting area: 1,220 x 2,500 mm (48.0 x 98.4") |

| CF22-1225RC-S | Effective cutting area: 1,220 x 2,500 mm (48.0 x 98.4") |

Specification Sheet

Application list

- Sign & Display

- POP

- POS Display

- Package

- Industrial Cut

[ID Cut] function enables easy Print & Cut combined operation

[ID Cut] function is to print the ID information to cut and media rotation angle to be able to read the job data automatically to start cut on [CF22-1225]. It saves labor of media direction check and avoids loss of media, ink and time due to data transmission or media set failure.

Mark-sensor function

With the adoption of a high performance color photo sensor, the square register marks printed on the media are detected and the position of the origin, inclination of coordinate and distance are adjusted.

This enables the operator to perform cutting at the precise position. Further, the sensor recognizes the difference of "color of media" and "color of square register marks", and enables the cutter to perform cuts accurately, while being tailored to the printed material without being influenced by the color of the media. A light pointer that is used as marker when setting the media is provided as standard device and facilitates position adjustment with square register marks.

Media is set easily and accurately

With the aid of a work-guide installed to the directions of X and Y, the positioning of the media is smooth and working efficiency has been improved. It is also possible to remove the work-guide depending on the media size.

1: Effective range of cutting

2: Media

3: Work-guide plate

4: Origin seal

Extensive line-up of cutter blades

A wide variety of cutter blades tailored to various media are provided. As one machine can process with flexibility, expand your business opportunities.

Cutter blades in the marketplace can also be used.

As the low cost cutter blades can be used, the running cost can be reduced.

Full of useful functions to support cutting

Half-cut

By adjusting the depth of the cutter blade, you can half-cut composite, laminated material (etc).

As two tools can be used, you can perform different types of half-cutting or diecutting without changing the tools.

Correction of starting and ending points

The starting and ending positions of cutting are corrected, which makes cut-away of the media smoother. Adjustable within the range of 0 to 2.5 mm.

Circle θcorrection

Declination of starting point and ending point of a circle cutting caused by thickness or hardness of the media is corrected and cutting nearly perfect circle is available.

Press correction

Pressure of tool coming down is corrected to ensure complete cutting.

Repeated cutting

Is capable of repeating the cutting up to maximum of 5 times changing the cutting pressure. With only one time of data sending, you can cut even thick material with high quality finish.

Back cutting

Back cutting is also possible by attaching mark chips to the back surface. From the front surface, excess cut is not seen making the finish beautiful.

Multiple registration of cutting conditions

Cutting conditions such as pressure, speed, scorrection of starting and ending points, circle θcorrection, offsets, etc. by tool may be registered for multiple times.