GRAPHTEC FCX2000 Series

FCX2000 Series

The FCX2000 flatbed cutter is the ultimate solution for prototyping and small production runs of rigid packaging media and other sheet fed materials. With Graphtec's medium to large flatbed cutting plotters, you have the right tool for contour cutting without requiring a die. Reduce media waste and processing time with included, dedicated software.

Added offline, USB operation enables operators of all skill levels to process various types of media for cutting.

Up to Kg Cutting Force & 400 mm/s Cutting Speed

[3] DIFFERENT MODEL SIZES

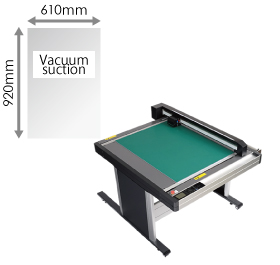

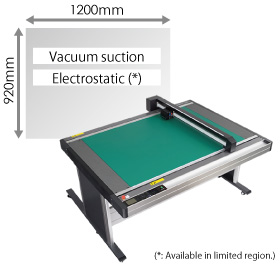

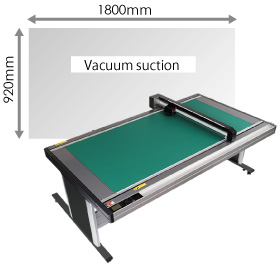

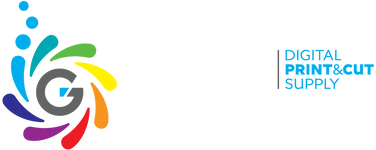

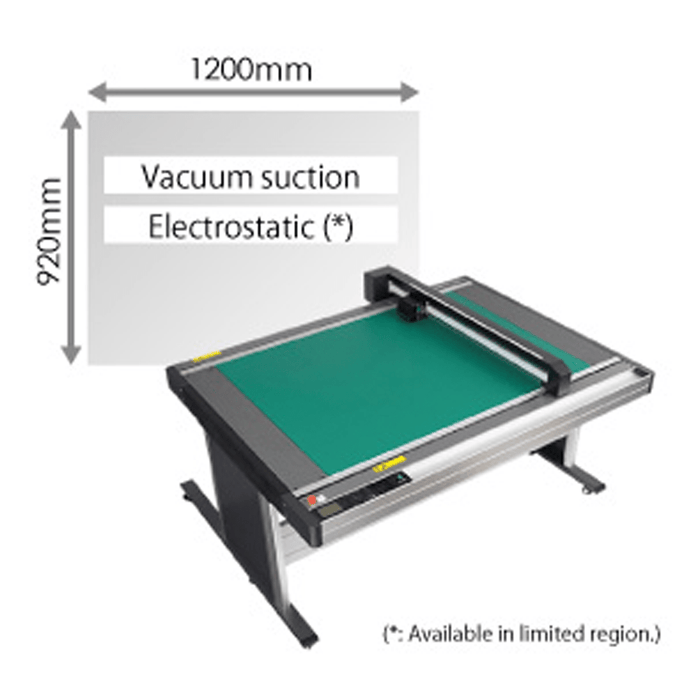

[3] different table size with choice of vacuum suction or electrostatic media-hold down methods depending on application.

FCX2000-60 (VC)

FCX2000-120 (VC)

FCX2000-180 (VC)

FEATURES:

VACUUM SUCTION: This holds media with the use of external electric vacuum pump. This is the preferred method for heavier and thicker media.

TWO PUMPS AVAILABLE: 110V HAS 1.5 HORSE POWER, 220V HAS 2.5 HORSE POWER

SUITABLE TOOLS FOR MANY APPLICATIONS

- The FCX2000 series has 2 tool holder in the carriage.

- Using 2 different kind of tool allows to do a different job without exchanging a tool at the same time; increasing work efficiency.

- Dual Tool Holders which can hold a cutting blade and creasing tool to produce creases/folds and cuts on the same run.

- Maximum Cutting Force - Tool 1: 500 gf, Tool 2: 1,000 gf

OFFLINE OPERATION

Cut and plot data is created with Cutting Master 4 or Graphtec Pro Studio. That saved data may be transferred to a USB flash memory and the cut plot data file can be selected from the USB on the FCX2000 using its menu operations. This simplified work-flow enables users to operate without being connected to the computer.

BARCODE DATA MANAGEMENT WITH USB FLASH MEMORY

When performing contour cutting, also known as Print & Cut, the cutting data is automatically selected from the prepared USB flash memory. The FCX2000 scans the bar code printed on the media then automatically performs the contour cutting job. This emerging method helps to prevent operator error of using incorrect data - thus improving workflow efficiency.

ENHANCED ARMS

(Advanced Registration Mark Sensing system) for improved productivity of P&C applications

- Enables higher productivity of POP, stickers, and prototype cartons.

- After data is sent the first time, it can be copied multiple times without a PC.

- The first four marks are scanned on the first sheet, and only the first mark in subsequent sheets. This improves productivity by shortening scan detection time.

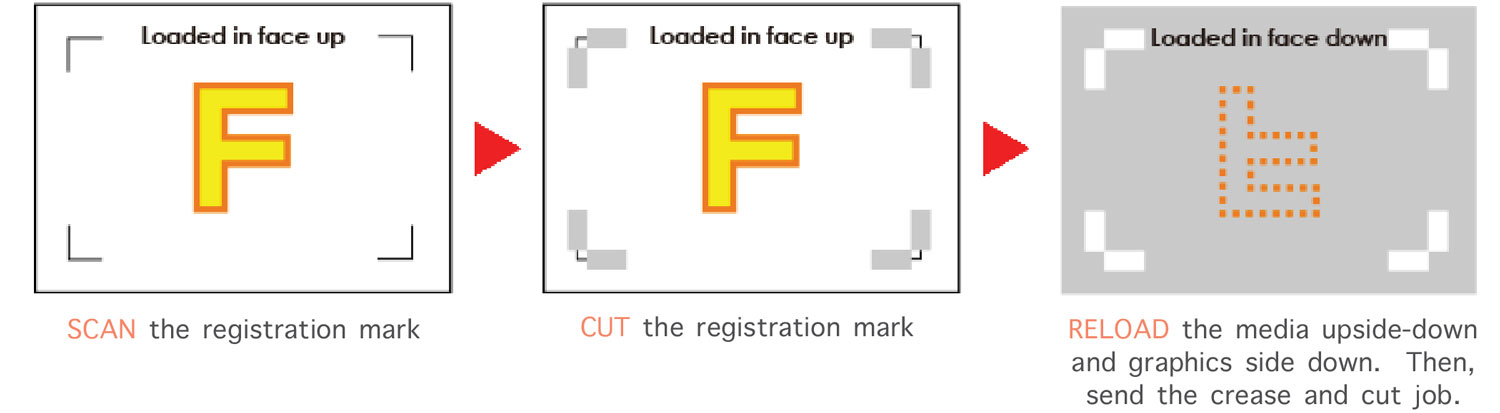

REVERSE SIDE CUTTING AND CREASING METHOD

REVERSE SIDE CUTTING AND CREASING METHOD

Cutting and creasing of pre-printed packaging graphics is possible on the reverse (non-printed) side of the sheet. This method of reverse side cutting and creasing prevents damage and marking of the printed side. This option is currently available using Cutting Master 4 or Graphtec Pro Studio software with the FCX2000.

EXPANDED CONTOUR CUTTING AREA

This included function expands the print and cut area to include objects outside of the registration marks! Production efficiency is enhanced and media waste is reduced.SUPPORTS STANDARD CROP MARKS

Contour cutting pre-printed media is also possible using ‚standard crop marks. This operation is available with the included Cutting Master 4 plug-in workflow.

REVERSED COLOR REGISTRATION MARKS

Registration marks are detectable when there is sufficient contrast against the mark and its background. Ultra glossy and reflective media offer challenges for accurate registration mark detection. With this reversed color output, the sufficient contrast is brought back for the ability to contour cut pre-printed ultra glossy and reflecting sheeting.

REVERSE SIDE CUTTING AND CREASING METHOD

REVERSE SIDE CUTTING AND CREASING METHOD