Keencut SteelTrak Multi-Substrate Cutter

|

SteelTrak cutters |

|

SteelTrak 165cm - 65" |

|

SteelTrak 210cm - 82" |

|

SteelTrak 250cm - 98" |

Perfect cut every time

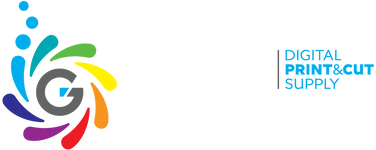

To ensure precision accuracy, the SteelTrak’s unique pressure-sensitive clamp can be first applied lightly to allow for fine adjustments, before the pressure is increased for a firm hold. The clamp is designed to protect delicate boards and printed surfaces. The sightline strip helps you achieve exact alignment and all the blades cut along the same line.

The SteelTrak gives you the flexibility to cut anything from PVC foamboard to steel composite panels. It’s more accurate, consistent, and reliable than any other machine on the market. In a single movement, you can slice easily through the toughest materials to leave a smooth edge with no need for extra finishing. Its unique features will speed up your production, whilst guaranteeing a perfect cut every time. The SteelTrak is the essential tool for a high-volume production unit.

Cut steel and aluminum composite safely and accurately

The newly developed SteelTrak C2 composite cutting head will cut steel composite panel, e.g Multishield and aluminum composite panel, e.g DiBond, in a single pass without creating dangerous sparks or dust. The new cutting head significantly reduces any curvature on the cut material to facilitate successful flat-bed printing and minimize waste. There is no need for extra edge finishing, so productivity is increased, and safety guaranteed.

Note: The SteelTrak is now supplied with the new SteelTrak C2 composite cutting head as standard. Existing SteelTrak users can purchase an upgrade.

Cut and finish large sheet materials in one pass

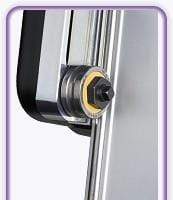

For those who need to cut larger sheet materials, the ST250 is the perfect choice. It will cut and finish 2.4m x 1.2m (8’ x 4’) sheet materials in one pass. Both the ST210 and the ST250 are fitted with an extendable arm to allow easy reach to the top of the machine.

Space saving and silent

The upright structure and wall mounting feature saves workshop space. The design uses your body weight to minimize the effort needed to cut tough materials. There is no noise and no need for electric power and the upright design and the low friction bearing system combined together reduces user fatigue.

Sign trays and much more

With the addition of the optional V-groove tool, the SteelTrak creates perfect sign trays, self-standing displays, boxes and exhibition stands. The V-groove tool fits directly onto the SteelTrak cutting head and is ready for action in seconds.

Five year guarantee

By manufacturing in-house, with only the highest quality materials, Keencut can guarantee that the SteelTrak will provide reliable long-lasting and accurate service. All Keencut products are offered with a comprehensive five year guarantee. Register your product to activate your guarantee >

In the box

100 medium duty utility blades

Twin wheel cutter

Spare sightline strip

Perfect for Cutting

Rigid materials

Aluminum composite panel e.g Dibond ≤ 4mm (1/8″)

Steel composite panel e.g Multishield ≤ 3mm (3/32″)

V-grooves Dibond ≤ 3mm (3/32″) with optional SteelTrak v-groover

MDF ≤ 3mm (3/32″)

Cast acrylic / Plexiglas (scoring only) ≤ 3mm (3/32″)

Glass ≤ 6mm (1/4″) with optional glass cutting kit (Product code: STGLC)

Semi-rigid materials

PVC foamboard ≤ 13mm (1/2″)

Corrugated/fluted plastic ≤ 13mm (1/2″)

Corrugated cardboard ≤ 13mm (1/2″)

Foam centered board ≤ 13mm (1/2″)

Mountboard ≤ 6mm (1/4″)

Aluminum sheet ≤ 1mm (1/25″) with optional cutting head ( Product code: STALC)

Optional Accessories:

V-groove attachment

Fast and simple way to construct sign trays, self-standing displays, exhibition stands and boxes from printed or unprinted aluminum composite panel (ACP).

Glass cutting kit

Includes everything to convert the machine for instant selection of glass cutting. Maximum cut length is 165cm (65”).

Free standing kit

Ideal for when wall space is limited or flexibility of machine placement is required. Bolts directly to the back of the machine to produce a rigid and stable free-standing unit.

Squaring arm extension

Allows easy large board handling on both sides of the cut.