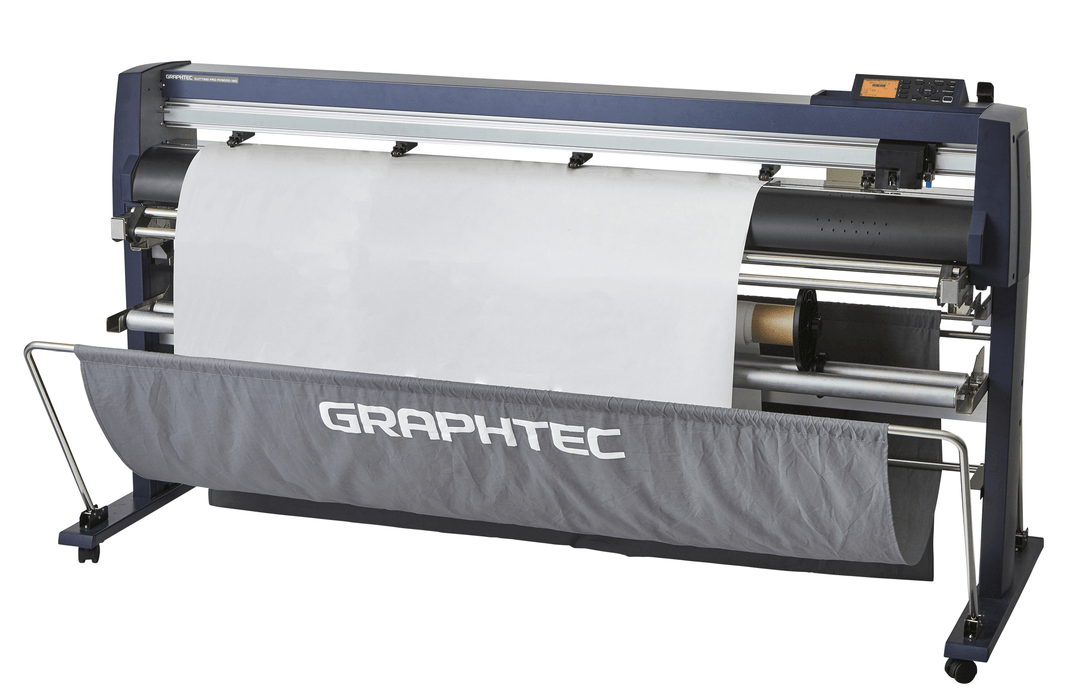

GRAPHTEC FC9000 SERIES -for $4,595 - Additional Fees May Apply

Graphtec FC9000 SERIES

FC9000-75 FC9000-100 FC9000-140 FC9000-160

The flagship FC9000 Series is Graphtec's most advanced, versatile roll fed cutting plotter to date. Revered around the world for its dependable, high-precision cutting capabilities with both printed and unprinted materials, the FC Series is the ultimate finishing solution for the wide format signage, apparel, and automotive industries. A newly developed feeding system and cutting head has further improved cutting quality of thin and thick materials ranging from delicate window tint to rigid magnet and high intensity reflective. ARMS 8.0 features the introduction of Graphtec's Datalink barcode generation system which efficiently loads and processes your jobs automatically.

Datalink Barcode

Save time and reduce the chance of production errors by using barcodes to automatically process multiple jobs at the touch of a button.

DataLink supports any combination of RIP software & printer in addition to included Cutting Master 4 and Graphtec Pro Studio software.

The FC9000 detects barcode-linked cutting data from the operator's PC or USB flash memory, opens the correct file, sets the cutting conditions, and starts cutting automatically.

Print and Cut Accuracy

Graphtec's Advanced Registration Mark Sensing technology delivers precise Print / Cut results in addition to efficiency boosting features.

The new white LED sensor and improved search algorithm accurately read registration marks printed from any printer onto a large variety of media types including high gloss, metallic, glitter, and high intensity reflective.

Heavy-Duty Cutting

No flatbed? no problem.

A re-engineered feeding system has greatly enhanced the cutting capabilities of thin and thick media types.

Add additional push rollers for increased precision when cutting heavy, rigid materials such as magnet, rubber, and diamond-grade high intensity reflective. Three pressure settings ensure strong media hold-down without leaving track marks.

Contour & Dye-Cut

Separate tool positions for contour and die-cutting ensures the longevity of your blades and cutting strip when creating decals and graphics that are effortlessly popped out of sheet and roll media.

Take-Up Reel

The optional take-up reel boosts production efficiency by automatically winding rolls of media up to 65 feet long with equipped infrared sensor.

Compatible with the FC9000-140 and FC9000-160.